Fontijne Holland – Experts for Sustainability

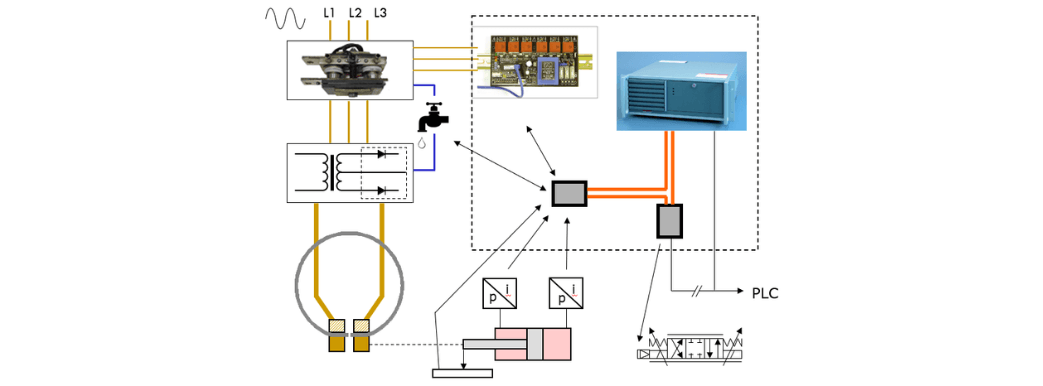

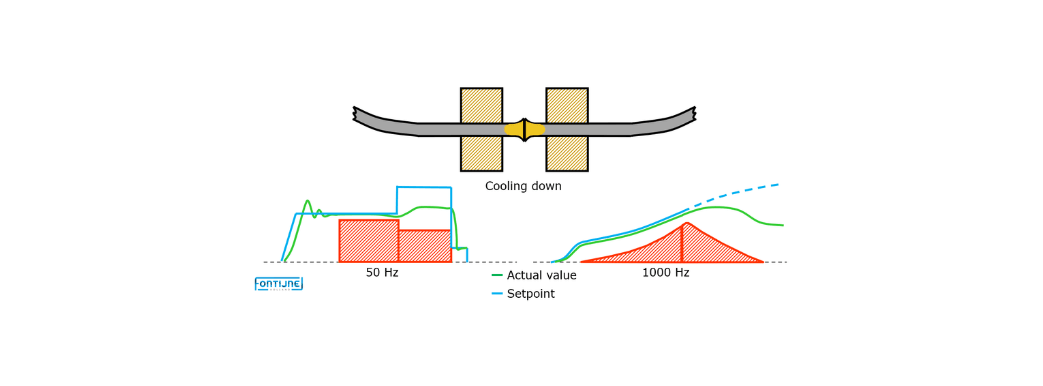

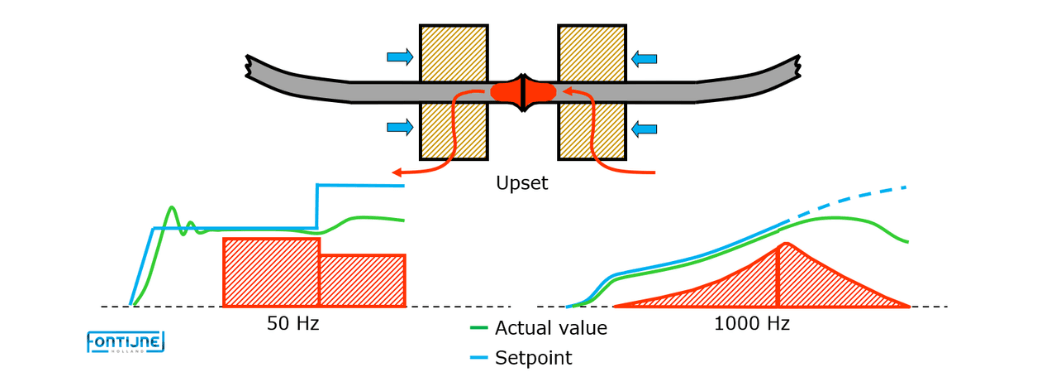

The Fontijne Holland Weld Control 2.0 (1000 Hz) is a unique temperature dependent*, closed loop, control system, which controls the heating phase by heating up the product to the yield temperature while holding the upset force and controls the upset phase by position control to reach the required amount of upset. The welding process is based on temperature, pressure and position. We are constantly developing the Weld Control system over the years, starting with Weld Control 2000 through Weld Control 2009 to Weld Control 2.0. The latest weld control system is designed to operate to its full potential on the state of the art dedicated Fontijne Holland welder. Furthermore, the Fontijne Holland weld control 2.0 (50-60 Hz) operates on all existing flash and flash less DC welders.

* The temperature dependent control requires specific hardware; to use the control system to its full potential the machine should be equipped with high speed servo hydraulic valves, high speed controls, sensors, etc.

Fontijne Holland offers different systems for the welding control in the wheel production depending on your requirements. The latest innovation is the Weld Control 2.0.

The Fontijne Holland weld control 2.0 combines various weld controls in one program. It has the following unique features:

The following weld controls can be replaced by the new Fontijne Holland weld control 2.0:

The Weld 2000 has the following unique features:

The Weld 2009 has the following unique features:

The Fontijne Holland lines do not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.