Valve hole pressing for off the road vehicle wheels

A valve hole press installation is designed to make a perfect valve hole in the rim. The valve hole is made on a predefined position in three steps: coining, punching and deburring. The area around the valve hole is coined to obtain an optimum valve seat surface. The valve hole is punched in the middle of the coined area. After punching, the valve hole is deburred for best prevention of damage to the valve.

The Fontijne Holland punching press, originally designed for wheel production, can also be used for other applications, where holes need to be punched.

The process of a valve hole press

Valve hole press

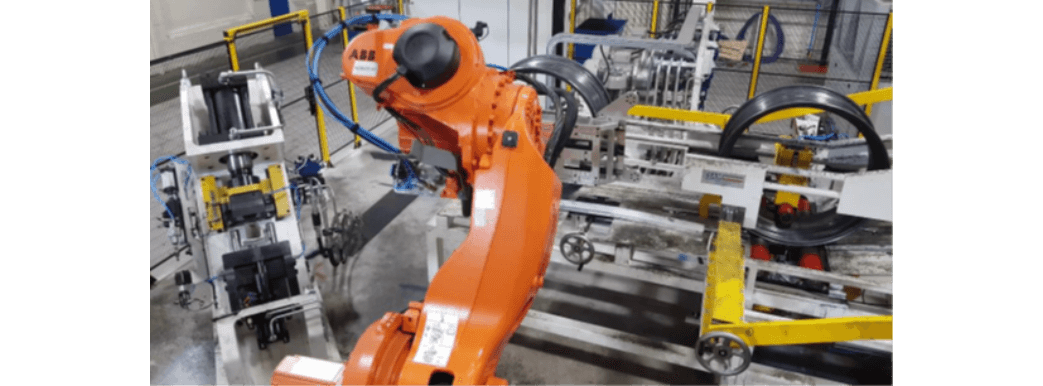

The valve hole is made at a defined position in the rim, this position is orientated in the transfer system at the entry position of the valve hole press. The robot places the rim in the press position after which the first cylinder will make the coining stroke. The hole will be punched by a second cylinder. The robot will move the rim to the side of the press frame where the deburring of the hole will be executed by a drilling unit. After the deburring cycle the robot will place the ring on an exit conveyor.

Unique features:

- Coining, punching and deburring is executed by one machine, equipped with two cylinders.

- Compact layout for small “foot print”.

- Handling by a robot, which holds the valve hole spot at correct position at all times.

Not the right one?

The Fontijne Holland lines do not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.