Rim production line for off the road vehicle wheels

A rim forming line is designed to transform a flared ring into a perfectly round and profiled rim. The flared ring will be formed into the required profile in three steps, guaranting high output, low wear on tooling and a perfect, unscratched surface of the rim. The final expander calibrates the ring to a perfectly round profiled shape.

The Fontijne Holland rim production line produces a high quality, perfectly round rim with the required profile. Originally designed for wheel production, the line can also be used for other applications, where a ring needs to be rolled to a profiled product.

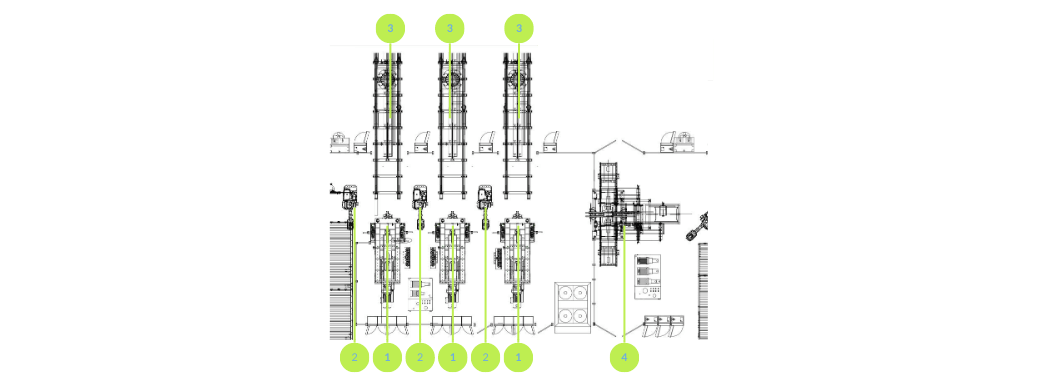

The process steps of a rim forming line for off the road vehicle wheels

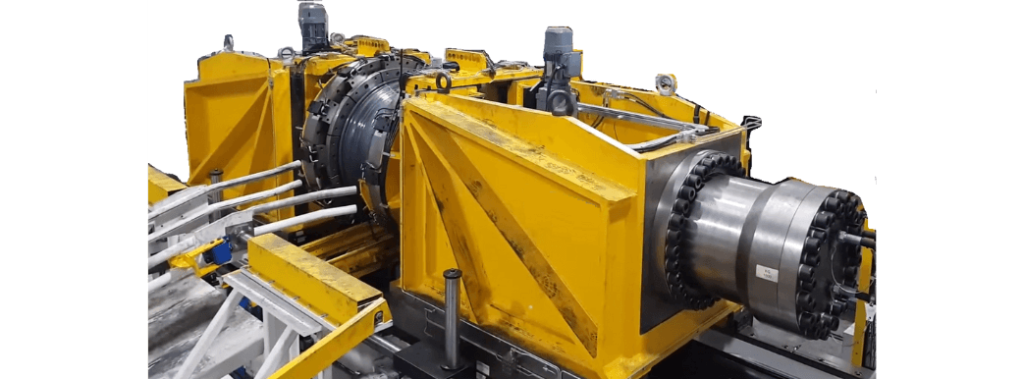

Roll formers

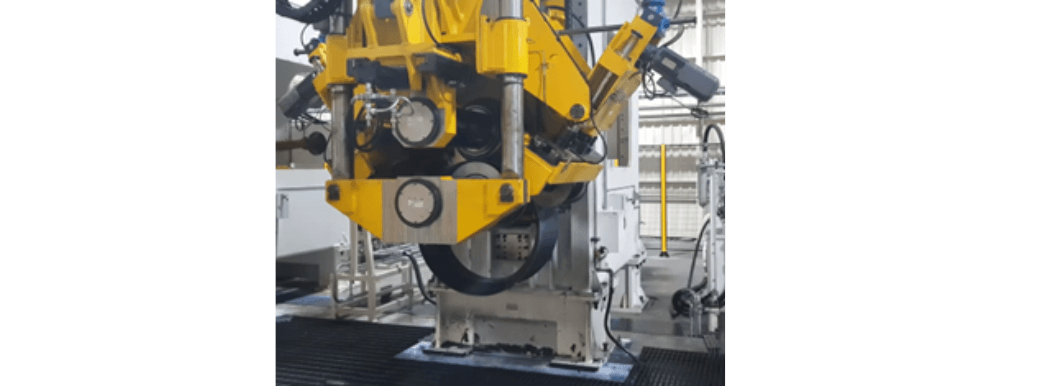

The roll formers form the profile in the ring. The profile is formed on three separate roll formers. Each product range has its own requirements. Fontijne Holland can provide double end as well as open end roll formers to suit applications:

Large diameter wheels

The open end roll former is more suitable for large diameter wheels. This type of roll former offers easy access to the tooling and stands out for simplicity in design.

Wide rims in combination with smaller diameters

The double end roll former is more suitable to be able to produce wide rims of smaller diameters. By supporting the spindle on both sides the bending of the spindle is kept to a minimum. The loading of the product is enabled by retracting the lower spindle while the upper spindle is located at a fixed position. The robot places the rim inside the roll former after which the lower spindle will extend and lock into the outer support block.

Very small rims

For the production of very small rims a split bottom double end roll former design is available. By splitting the tooling in the middle the diameter can be made even smaller than the tooling for the retracting spindle.

Knurling

It is possible to apply knurling to the bead seats on an optional, separate station.

Unique features:

- The rotary movement is executed by energy efficient, electrical driven spindles.

- Open end spindle for easy access to the tooling.

- Open end spindle for easy loading and unloading of the product.

- Double end spindle support causing less bending of the spindle for very wide rims.

- Height and angle adjustment for side guides.

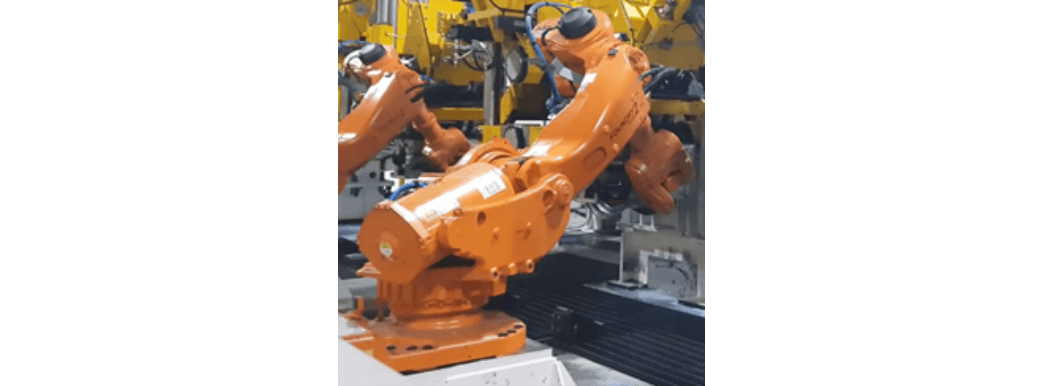

Roll former loader

The rims are loaded and unloaded to the roll formers by a robots.

Tool changers

Optionally, the roll formers can be equipped with auxiliary tool change devices.

Unique features:

- The new tooling can be placed on one side, the old tooling slides to the other side of the tool changer. No lifting is needed.

- Enables fast tool change times.

- Safe for operators.

The final expander calibrates the rim by sizing it to a final dimension with a perfect roundness.

Unique features:

- Easy adjustable final dimension by servomotor.

- Quick change procedure of expander heads.

Not the right one?

The Fontijne Holland rim production line does not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.