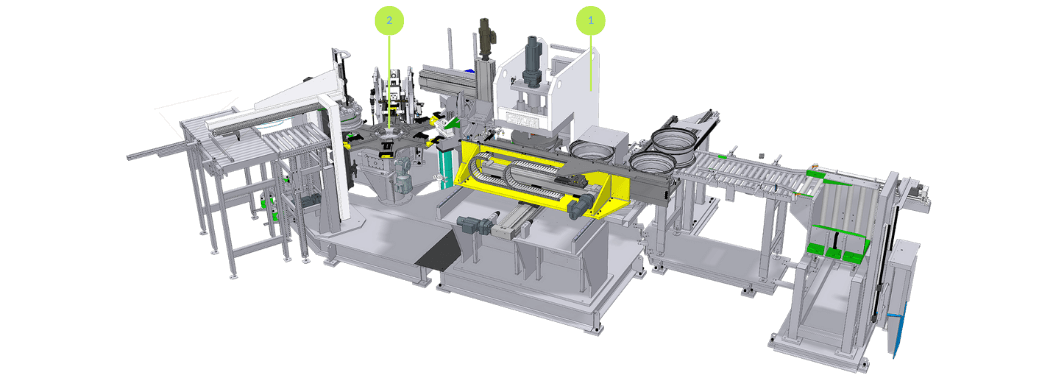

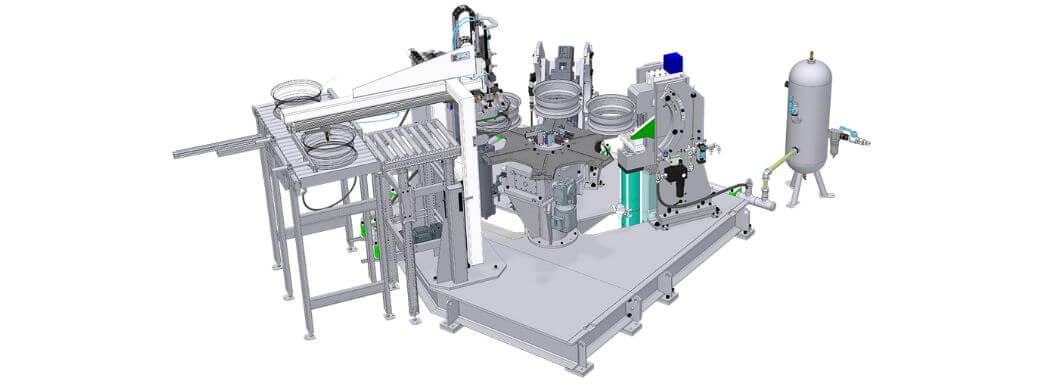

Leak detection and valve hole pressing

The leak detection process is designed to find very small leaks. The valve hole is made on a predefined position in four steps: valve hole angle off-set, coining, punching and deburring.

The leak detector detects extreme small holes and cracks in the weld area. The unique thermal detection system is contactless and requires minimum maintenance. The smart design ensures a sustainable solution by using compressed air of just 2 bar maximum. The leak detector has the same cycle time as the wheel production line and can be placed in-line and is therefore capable of measuring all wheels resulting in optimum quality control.

A valve hole press installation is designed to make a perfect valve hole in the rim. When the valve hole seat has to be set to a different angle it is possible to change the angle in the first press-step. Depending on the necessary conditions several solutions are available: The area around the valve hole is coined to obtain an optimum valve seat surface. The valve hole is punched exactly in the middle of the coined area. After punching, the valve hole is deburred for best prevention of damage to the valve. The transport system of the valve hole installation guarantees a perfect positioning at each process step.

The Fontijne Holland leak detector, originally designed for wheel production, can also be used for other applications, where possible leaks need to be detected of tubular parts.

Leak detector

The leak detector is able to find very small leaks.

Unique features:

- Unique thermal detection system for high accuracy and fast response.

- All sensitive parts for detection are placed in a safe area of the leak detector, away from the product area and possible pollution.

- Easy and fast exchange method for tooling.

- Minimum maintenance required.

- Measuring medium is plain compressed air (less than 2 bar operating pressure for low CO2 emissions).

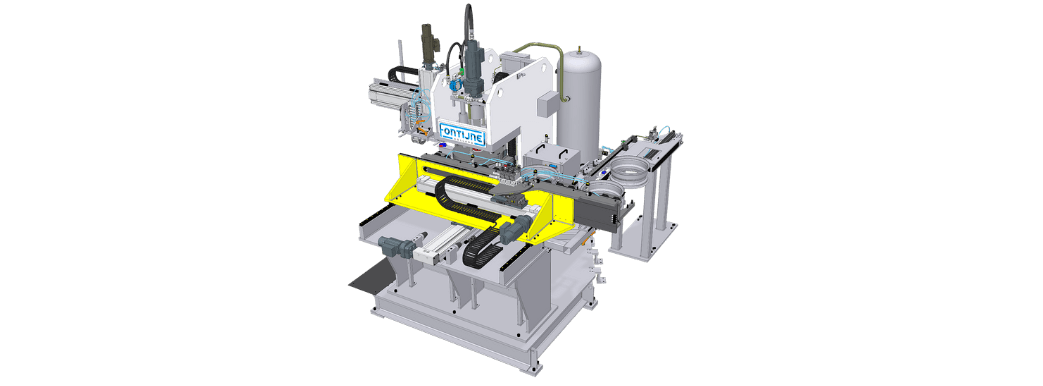

Valve hole installation

The valve hole is made at a defined position in the rim. This position is orientated in the transfer system at the entry position of the table.

Unique features:

- Valve hole angle off-set, coining, punching and deburring is executed by three separate presses.

- Compact layout for small “foot print”.

- Transport system, which holds the valve hole spot at correct position at all times.

Not the right one?

The Fontijne Holland lines do not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.