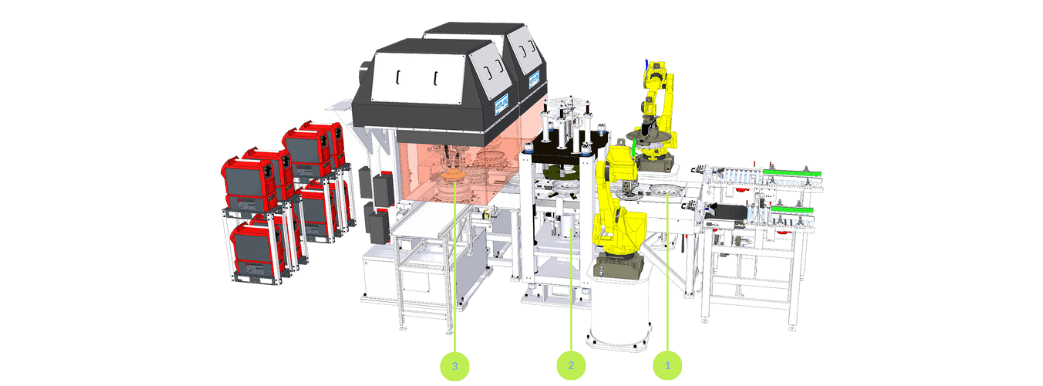

Wheel assembly line

The wheel assembly line, also known as rim and disc assembly line, is designed to position and press a disc into a rim to form a final wheel. The press is designed to press and hold the disc at a defined position and keep the disc perpendicular to the bead seats of the rim, at all times to keep the run out to a minimum. The torch welders are adjustable to obtain a perfect weld at all positions. The transfer system holds the wheel at a defined position at all times.

The Fontijne Holland wheel assembly line, originally designed for wheel production, can also be used for other applications, where two tubular products need to be attached and welded automatically.

The process steps of a rim and disc assembly line

The rim and the disc are positioned and placed on the conveyor of the assembly press.

Unique features:

- The disc is placed in the rim at a pre-defined position in relation to the valve hole by using a vision system.

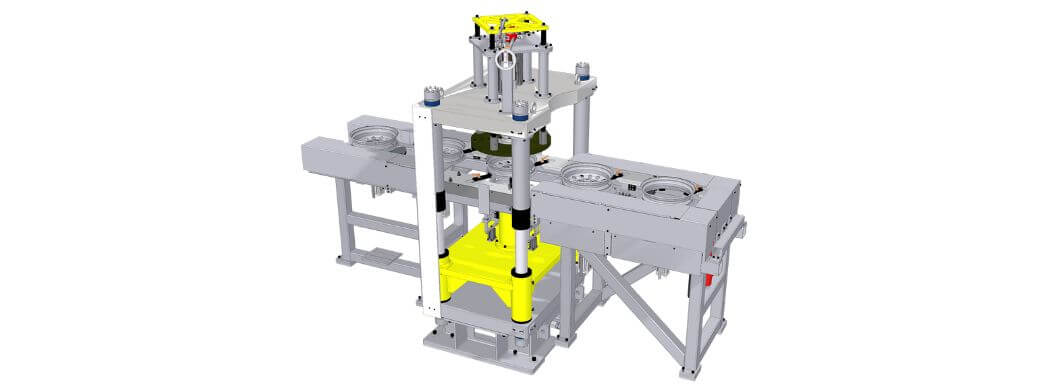

Assembly press

The disc is pressed into the rim by the assembly press.

Unique features:

- The press process ensures accurate perpendicularly of the disc in relation to the bead seats of the rim.

- The rim is supported at both sides during the press movement.

- The disc is clamped before the press. operation is started

- The assembly press installation is able to process well attached wheels and bead seat attached wheels.

- The transfer maintains the correct position of the disc in relation to the rim during transport to the press.

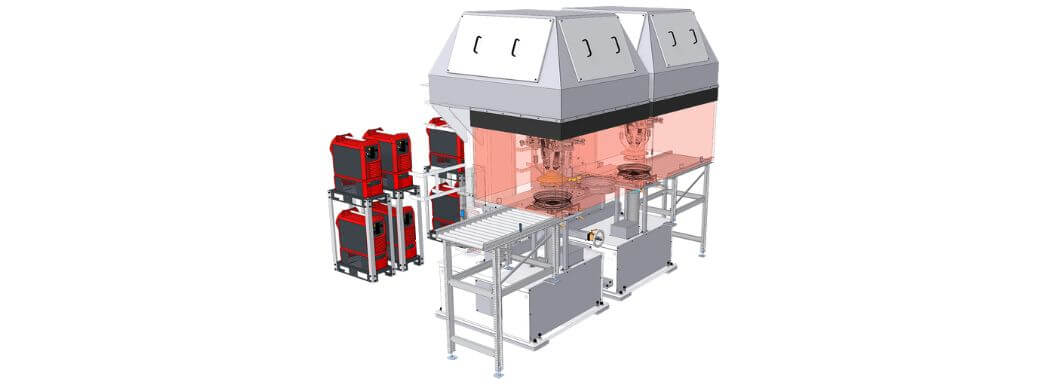

Assembly welder

The assembly welder welds the disc to the rim.

Unique features:

- Each weld section is executed by an individual torch to obtain fast cycle times.

- Easy central diameter adjustment.

- Automatic distance following system for correct height of torch in relation to disc edge.

Not the right one?

The Fontijne Holland wheel assembly line does not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.