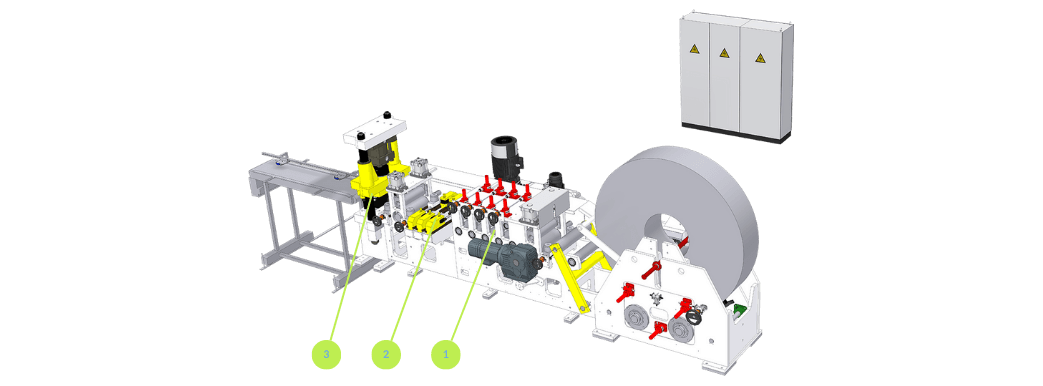

Cut to length line for commercial vehicle wheels

The cut to length line for commercial vehicle wheels transforms coiled, slit metal into straight sheets of required length for further processing. The line is designed to operate within a fully automatic production line or as a standalone machine to provide value added services while processing coil to piece.

The coil of material will be unwound to form a long strip.The strip is straightened to ensure a straight plate, which will be easy to handle in the ring preparation line. The longitudinal edges are rounded for optimum quality and to prevent damage to the tooling of the rim manufacturing line. Finally the strip is cut (perfectly perpendicular) into sheets of precise length.

The Fontijne Holland cut to length line, originally designed for wheel production, can also be used for other applications, where a coil of material needs to be unwound and cut into a perfectly straight plate.

The process steps of a cut-to-length line

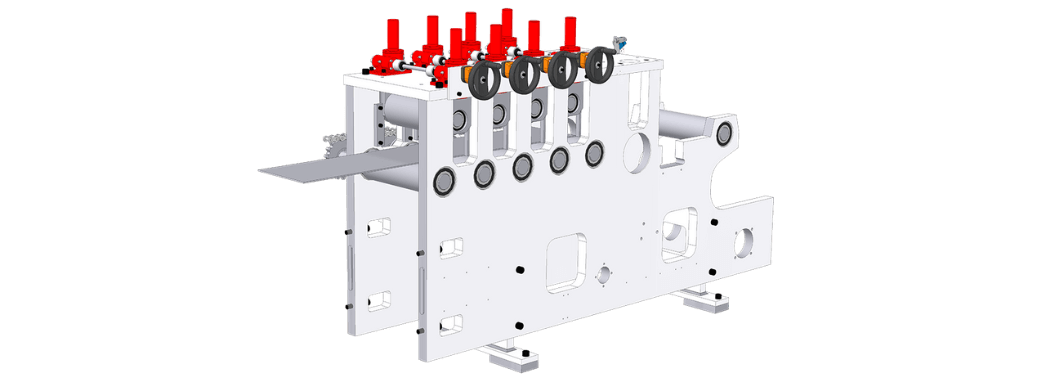

Straigthener

The straightener forms the strip into a straight plate. The material is bent several times between rolls. The user can set the amount of deformation.

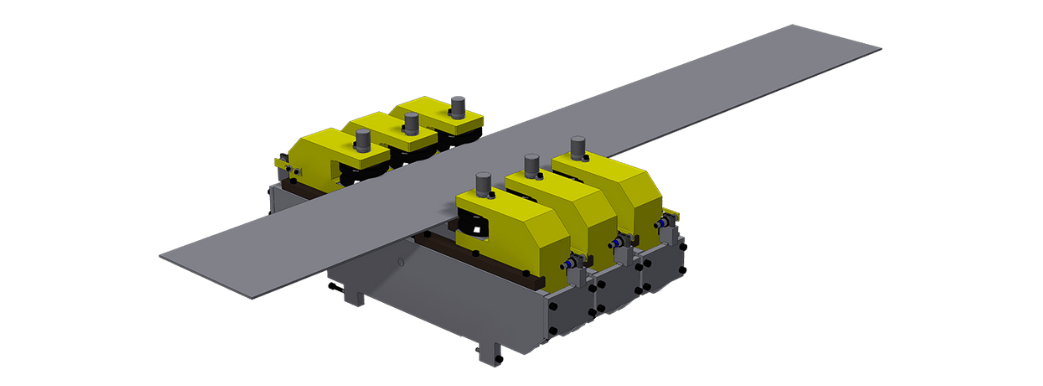

Edge roller

The edges of the plate are rounded by special shaped rolls.

Unique features:

- The rolls are quickly removable.

- Rolling instead of machining, thus no chips, which can stick to the plate causing damage to the product or tooling.

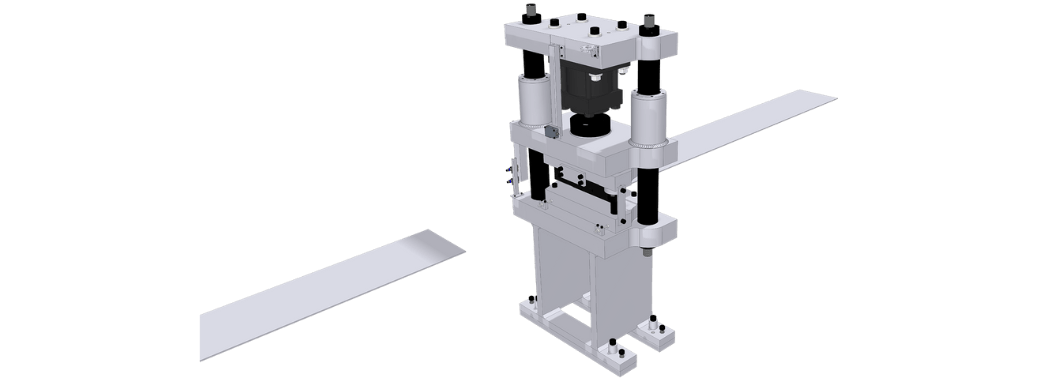

Shear

The material is cut into plates of precise length by a shear with an upper and a lower blade

Unique features:

- The plate is clamped while cutting, to prevent the plate from tilting during cutting.

- The unique shape of the blades ensure an equal load to the plate for a straight cut.

- The shear block is designed as a cassette module for easy removal.

Not the right one?

The Fontijne Holland cut to length line for commercial vehicle wheels do not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.