Automation in the wheel production

Automation of manual loaded and unloaded machines enables higher and saver productivity and higher and more consistent quality of your product.

Process that can be automated with Fontijne Holland automation

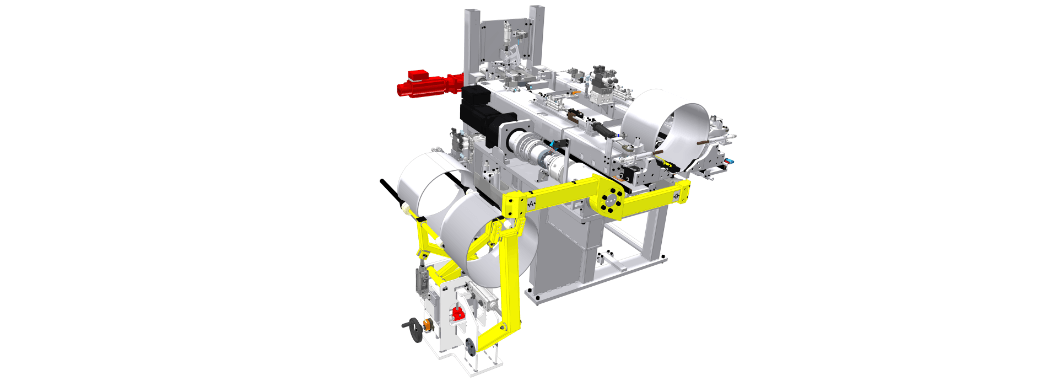

Coiler-flattener to welder

The automation of the transport from the coiler-flattener to the welder is very important for the quality of the weld. The alignment of the plate ends must be perfect and during the transport of the product to the welder this alignment must be secured.

Unique features:

- Offset in height between the ring ends will be eliminated.

- V-shape of the ring ends is corrected.

- Offset between front and rear of ring ends will be realigned.

- Constant loading quality lowers overall scrap rate.

- Increased safety.

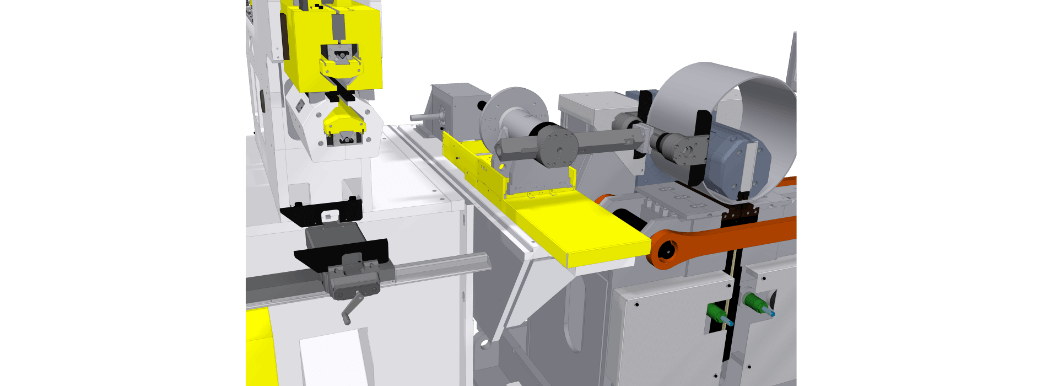

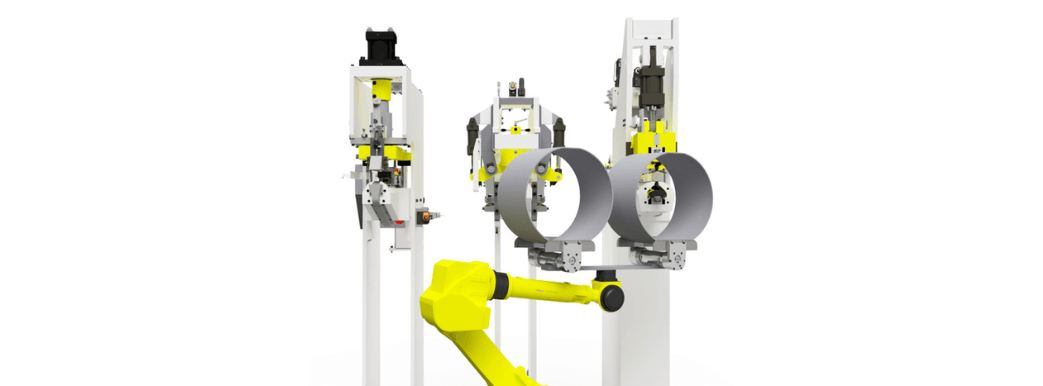

Swinging arm

The swing arm transports the ring from the welder to the trimmer.

Unique features:

- Accurate loading.

- High throughput.

- Rotation of the ring, placing the weld from bottom to top.

- Easy alignment of weld in weld dresser station (trimmer).

- Increased safety.

Transfer for welddresser

The transfer is a quick and accurate loading / unloading device for the welddresser.

Unique features:

- Accurate loading.

- High throughput.

- Loading without scratching the product (by means of lift movement).

- Increased safety.

When automation is required for manual loaded stand alone trimmer, roller and side trimmer, the automation can be executed with a robot.

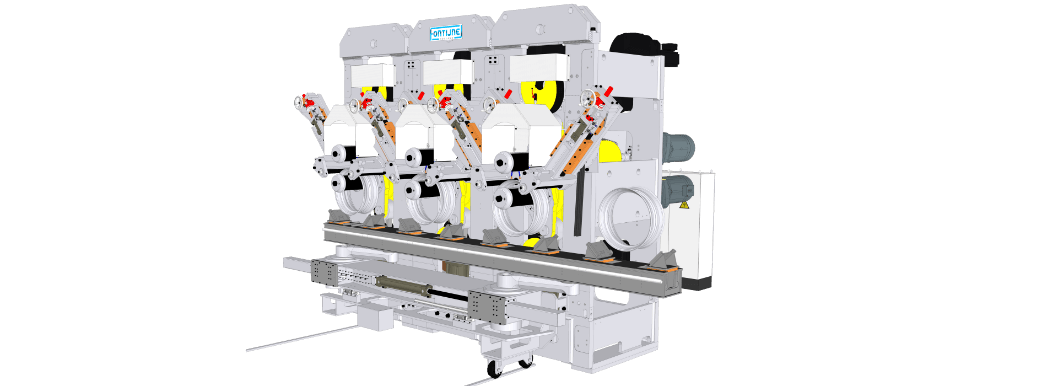

The loader beam is a quick and accurate loading / unloading device for the roll formers.

Unique features:

- Accurate loading.

- High throughput.

- Small footprint.

- Increased safety.

When automation is required for manual loaded stand alone roll formers, the automation can be executed with robots.

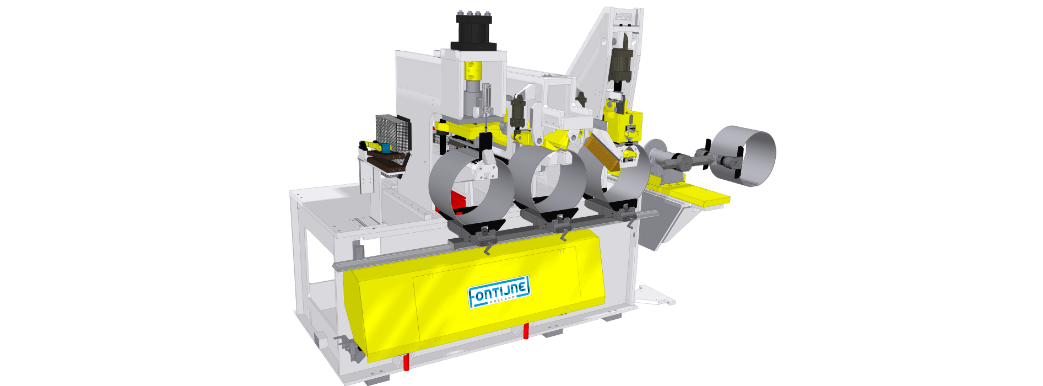

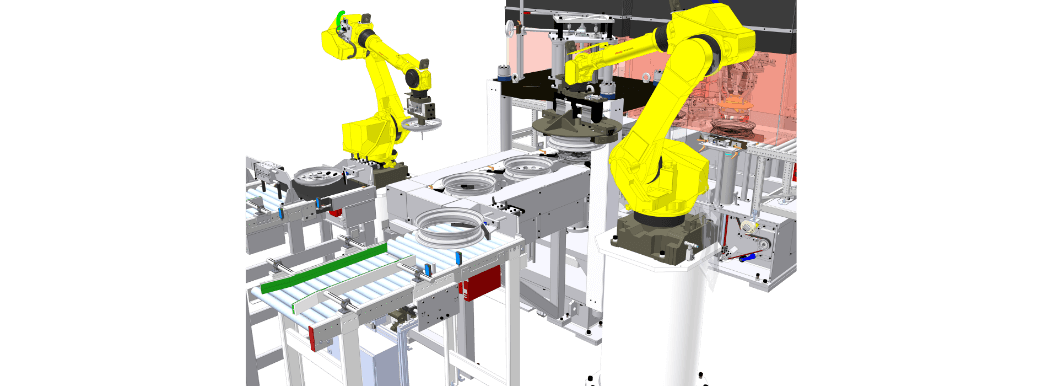

Rim and disc assembly

The automation of the rim and the disc assembly includes handling and positioning of the rim and disc and placing them on a transfer to feed the assembly press.

Unique features:

- Accurate loading.

- High throughput.

- Positioning of the disc hole pattern in relation to valve hole position in the rim.

- Constant quality of positioning hole pattern on all products.

- Perpendicular loading of the disc in the rim.

- Increased safety.

Not the right one?

The Fontijne Holland lines do not only manufacture rims. Any sheet metal product that needs to be formed and/or profiled, can be produced on our equipment. If you need assistance with the production of your products, please contact us.