Fontijne Holland visits SEW

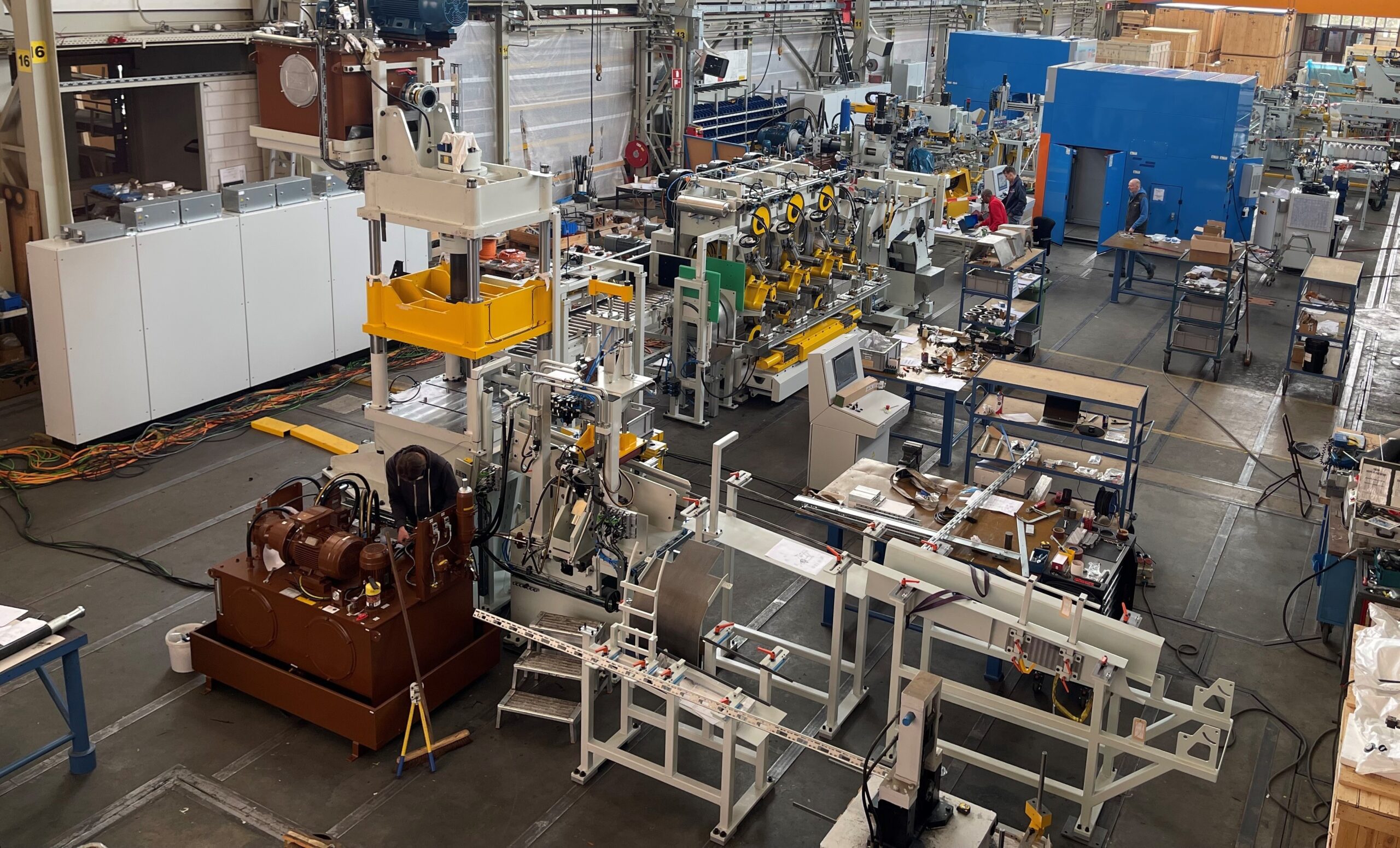

Factory visit to SEW factory in Graben Neudorf

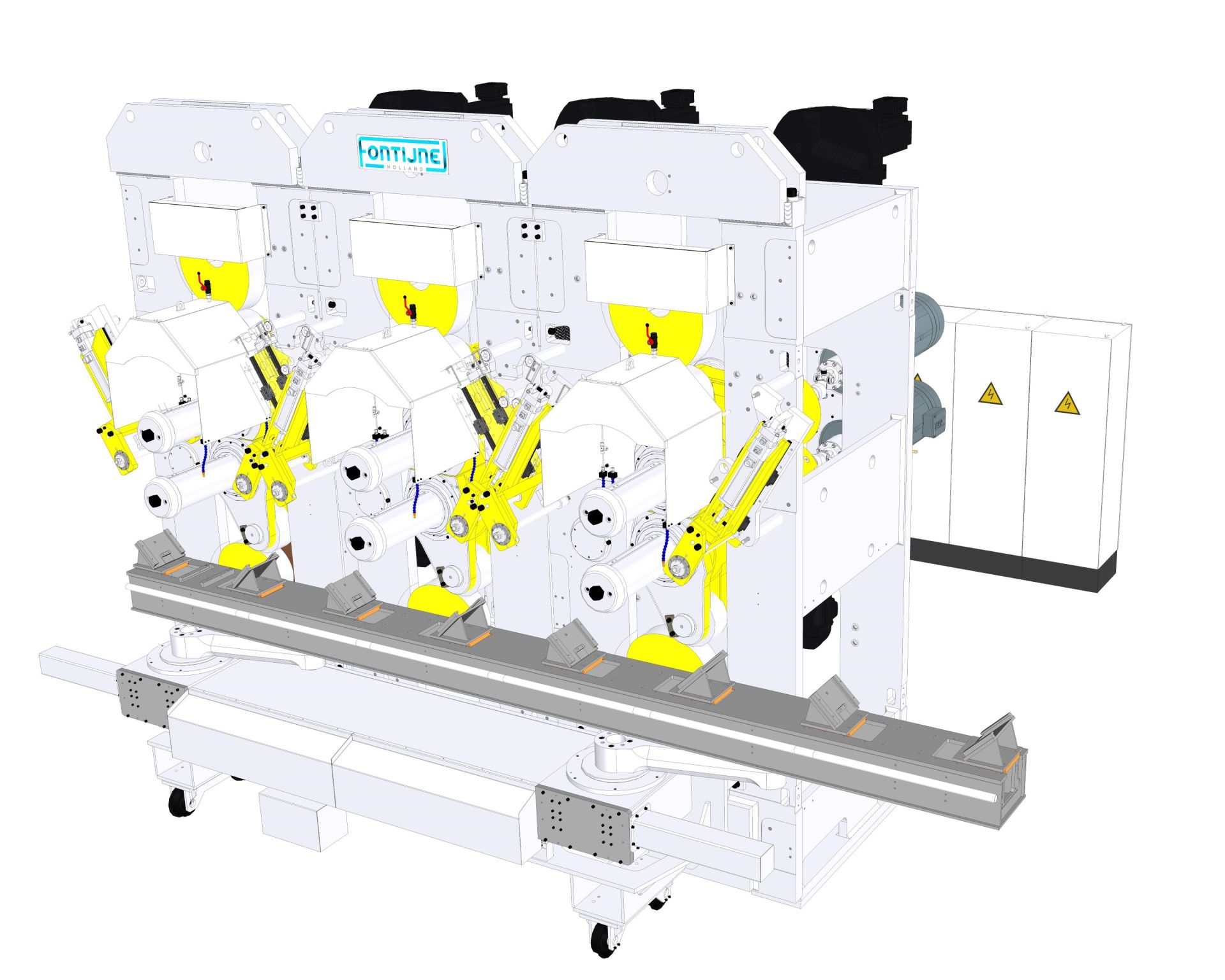

SEW has organized a company visit for regular customer relations. Fonijne Holland has cooperated with SEW for decades and was therefore invited to SEW in Graben-Neudorf on Oct. 8 and 9. The general impression gained during the visit is that there is an exceptionally high level of quality that SEW has guaranteed in this production facility. SEW’s quality is the foundation on which Fontijne’s machines are built. Making the Fontijne production lines more sustainable includes making drives electric, using SEW products. This visit has contributed to the confidence in the product and the cooperation, and from here we go further into the future.

Fontijne Holland: Experts for Sustainability!