Fontijne Holland – Experts for Sustainability

We design and manufacture quality wheel production equipment and processes for the wheel industry that are tailor-made to the needs of our customers and OEM demands, all over the world. Our equipment ranges from stand-alone machines with manual handling and loading, to fully automated turnkey production lines.

With our equipment market leaders in the wheel industry produce a wide range of rims and wheel sizes – from passenger cars to off-road vehicles, from commercial- to agricultural- vehicles and from trailers to golf cars and scooters.

Our knowledge and experience in this market segment is extensive and used to realise innovative and optimised products that are tailored to the market requirements of the automotive industry. Today, these requirements are principally geared towards stringent environmental standards (targeting a reduction in CO2 and other emissions); they also focus on improving the quality of the end product and making the production process considerably reliable.

We are the market leader in the development and optimization of wheel manufacturing processes, which leads to several advantages such as material savings, energy savings, improved product quality, reduced weld scrap rates, efficiency and reduced cost of ownership.

In addition to wheel production line equipment, we also offer a range of test and quality management systems that our customers utilize to manage their quality processes. A Fontijne Holland wheel production line is able to collect data, which can be used analyzing the production processes, as part of Industry 4.0. Furthermore, it can also include leak testers for testing rims and wheels, rim-edge conditioning systems to finish the rim edge quality and runout reducers to create a near-perfect runout.

Our vision is sustainable technology for the wheel production industry. We provide state of the art equipment with green and sustainable solutions, worldwide, to satisfy our customers and our society. Innovation and development, with our experienced employees, is the greatest asset to fullfill our goals.

We respect our customers and cultures, aiming for customer satisfaction, with our dedicated employees and partners. We also do underwrite the code of conduct and the code of ethics.

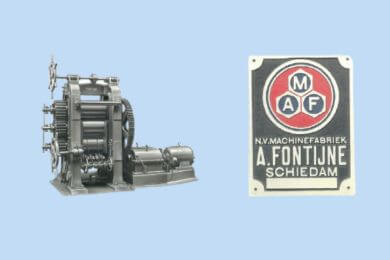

The Fontijne Holland roots are more then 100 years old, for more than 60 years designing and manufacturing wheel production lines.

Few things changed the world as much as the invention of the automobile in 1885, but it only became affordable for almost everyone with the invention of the assembly line. Henry Ford started the mass production of his legendary Model T in 1913. Only four years before that, in 1909, Fontijne Holland was founded.

Through a license agreement in 1963 with Grotnes Metalforming Systems, Fontijne Holland entered into the wheel manufacturing industry. In the year 2000 Fontijne Holland acquires Grotnes Metalforming Systems.

Wheel designs and their mass have a direct impact on the vehicle’s overall energy efficiency. For this reason, we decided over 20 years ago to create green and CO2 reducing wheel manufacturing lines.

2001 we supplied a first rollformer with low energy consumption, electrical driven, spindles. In 2007 we invented a new design of leak detection machine with low pressurized, energy savings solution. Only two years later, in 2009, we introduced a brakethrough in the welding process, with our TC Weld 2009 were the temperature in the weld seam was measured, based on a more energy friendly 1000 Hz weld system for butt welding machines. And in 2022 we have started to design a fully electrical operated rollformer as a part of the ”Green Line” project. Also in 2022 we were able to acquire the intellectual property from ESAM in Italy, herewith we can serve also the off-road market.

2016 was a tough year for Fontijne Grotnes. After being active for more than 100 years, the company had to close. But only for a short period of time, because some people believed in the market and their customers. They were convinced of the high quality equipment and processes and had a vision. So they restarted and founded Fontijne Holland in 2017.